Our reference projects

-

References by industry

-

References by country

KTI Senegal | Ice plants for Senegal

KTI Senegal | Ice plants for Senegal

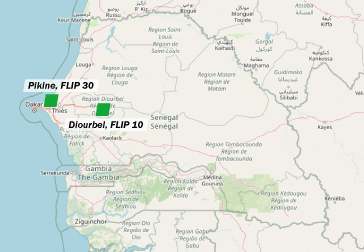

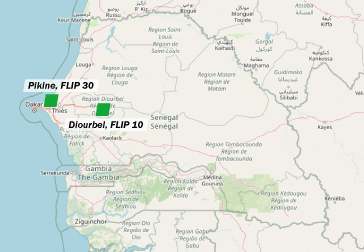

In June 2021, KTI Senegal was founded as a subsidiary of the KTI Group. The first industrial ice plant with a production capacity of 10 tons was opened in Diourbel in November 2023. The commissioning of another flake ice plant at the fish market in Pikine is planned for January 2024. The targeted expansion and development of further locations is planned for the course of 2024.

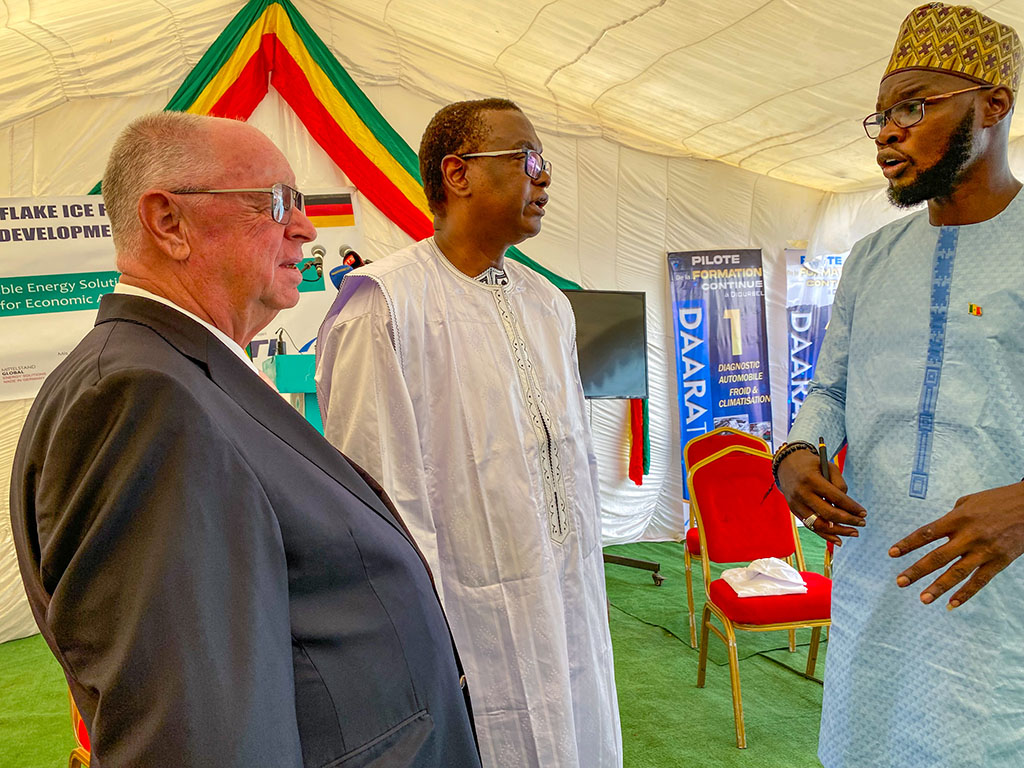

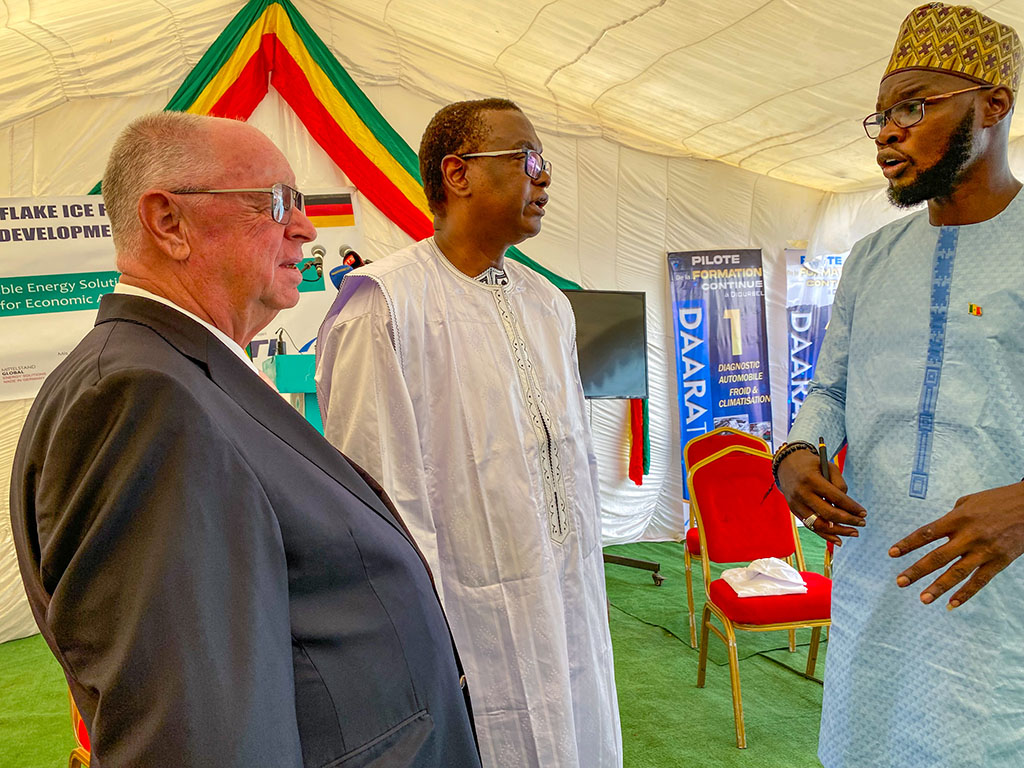

Opening

Impressions of the opening

Food saved is just as important as food produced

"Food saved is just as important as food produced. 80% of the 828 million people affected by hunger in 2021 lived in rural areas. Yet 70% of food in Africa is produced by smallholder farmers who own 1-2 hectares of land but are among the world's poor, living on less than 2 dollars a day. Interestingly, the food lost and wasted can feed 1.26 billion hungry people per year. In 2017, around 12 % of the food produced globally was lost due to the lack of efficient cold chains, 63 % of which was in low-income countries. The loss of food due to lack of cold chains is also estimated to cause emissions of 1 gigatonne of CO2 equivalent, which accounts for a third of total global emissions from food loss and waste.

Mary Najjuma

(PHD candidate at London South Bank University)

Advantages & features

- Energy-efficient and sustainable

- Turnkey and modular

- Environmentally friendly

- Cost-effective

- Natural refrigerants

- 40% less energy than Freon

- ODP and GWP =0

Technical properties

- Flake ice production: 10 tons per day

- Water inlet temperature: < 25°C

- Max. Ambient temperature: 45°C

- Refrigerant: R717 (ammonia, NH3)

- Engine room: 20-foot container

- Ice storage: 20-foot container (insulated)

Automatic loading, manual emptying - Ice storage temperature: -5°C

Combined heating and cooling system for ready-mix concrete batching plant

365 days of temperature-controlled concrete production with KTI's CombiMaster CM50 in Austria

Lorum ipsum dolor sit amet

Compact installation makes it possible

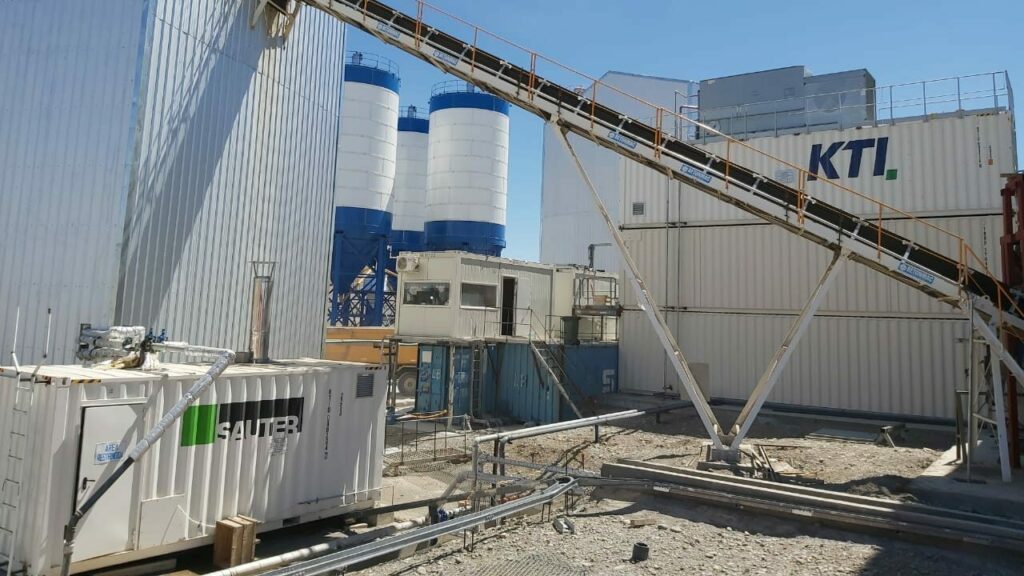

Gotthard Tunnel - SAUTER heating systems for the construction of the second tube

Gotthard Tunnel - SAUTER heating systems for the construction of the second tube

Lorum ipsum dolor sit amet

Purely electric - heating systems without emissions

In June 2024, KTI delivered SAUTER concrete heating systems to Airolo. In this project, not only does the issue of concrete temperature play a central role, but also the requirement to supply a system that produces no emissions, as work is carried out directly in the tunnel. This meant that a specially adapted solution had to be developed.

Concrete heating systems for the project of the century in Switzerland

365 days of temperature-controlled concrete production with KTI's CombiMaster CM50 in Austria

Lorum ipsum dolor sit amet

Specialized systems for extreme temperatures

The Grimsel dam project in Switzerland is one of the most challenging and important infrastructure projects in the Alpine republic. At an altitude of over 1,900 meters, extreme climatic conditions become an everyday companion during construction. KTI is proud to have made a significant contribution to the successful implementation of this project with its innovative SAUTER concrete heating technology.

A new ice plant creates sustainability

Highly efficient and sustainable flake ice plant for Peterhead

In 2024, we installed a flake ice system for Europe's largest fishing port in Peterhead, Scotland. With annual fish landings valued at over £230 Million, the necessity of ice for maintaining fish quality the port's outdated ice plants could no longer cope with the ice demand. The provision of the new flake ice plant will ensure the future viability of the local fishery and the fishing industry in general. We at KTI were able to convince the Peterhead Port Authority with our unique expertise in the manufacture of systems for ice production, ice storage, ice weighing and ice transportation. Attention was also paid to the use of the highest quality components and materials during the engineering phase. The result: a flake ice plant that far exceeds all industry standards.

Our state-of-the-art installation includes a plant that produces 75 tons of flake ice per day and an ice store with a storage capacity of 100 tons, which is equipped with a rake system for fully automatic operation. The use of high-quality stainless steel is a matter of course in order to meet hygiene standards as well as the requirements for installation directly on the quay wall. For sustainable and "green" operation, Peterhead Port Authority has opted for ammonia (R717) as the refrigerant. As a special feature, it should be mentioned that the system is recooled using the seawater that is already present. By choosing the refrigerant and the seawater cooling, our engineers created a highly efficient and sustainable solution that sets new standards. To ensure longevity despite the use of seawater, titanium was chosen as the metal for the components, which in turn emphasizes the special nature of the system. The port itself has installed a 150 kWp photovoltaic system on the roof of the adjacent fish market. We were also able to supply the necessary space for switchgear and equipment. Our state-of-the-art installation includes a plant that produces 75 tons of flake ice per day and an ice store with a storage capacity of 100 tons, which is equipped with a rake system for fully automatic operation. The use of high-quality stainless steel is a matter of course to meet hygiene standards as well as the requirements for installation directly on the quay wall. For sustainable and “green” operation, Peterhead Port Authority has opted for ammonia (R717) as the refrigerant. As a special feature, it should be mentioned that the system is recooled using the seawater that is already present. By choosing the refrigerant and the seawater cooling, our engineers created a highly efficient and sustainable solution that sets new standards. To ensure longevity despite the use of seawater, titanium was chosen as the metal for the components, which in turn emphasizes the special nature of the system. The port itself has installed a 150 kWp photovoltaic system on the roof of the adjacent fish market. We were also able to supply the necessary space for switchgear and equipment. The commissioning of the new ice plant will make supplying the fishing boats and the nearby fish market much easier and more efficient. The boats can load ice onto their vessels from the water. A new solution was developed for this purpose, which enables the ice conveyor unit to be swivelled, raised and lowered fully automatically. This ensures that the fish is optimally cooled immediately after being caught and thus reaches customers at the fish market in top quality. With the purchase of the KTI flake ice systems, the port of Peterhead remains a central hub for the fishing industry in the region, ensuring the highest standards in fish processing through the use of state-of-the-art refrigeration technology.Technical data + installation details

- Flake ice plant, type FLIP75

- 75 tons of ice per day, 2 mm thick

- Ammonia as a natural refrigerant

- 100 tons of ice storage, type MIS100

- "Stainless steel"

- "Seawater-cooled"

- Weighing system, WSC450

- Billing system, KISS

80 tons of ice production for Scottish salmon processor

Flake ice plant for salmon processing

In 2019, we installed a flake ice plant at a Scottish salmon processing company. As our customer continues to expand their business, there was a need for more ice to pack the salmon. The limited space in the existing building once again highlighted the benefits of our container solution when we installed a flake ice plant next to the building with a production capacity of 80 tons per day.

Our turnkey installation includes a plant for the production of 80 tons of ice per day with an automatic ice storage with a capacity of 40 tons. A substructure, stairs and platforms, and an ice conveyor system complete the installation along with smaller accessories. We started the construction at the end of July 2019 and the whole setup was fully commissioned after only about 6 weeks. Flake ice production takes place on ice makers with chrome-plated surfaces. The refrigeration cycle is air cooled and an economizer together with the use of NH3 / ammonia as refrigerant leads to highest energy efficiency. Ice storage takes place in a stainless steel tank with our reliable air circulation channels to keep the internal temperature below freezing and ensure optimal storage of flake ice. An automatic ice rake constantly levels the ice and discharges it when needed. The ice transport system then delivers the ice to multiple ice feeders, which weigh it and pack it into insulated boxes ready for shipment, along with the fresh salmon. Alternatively, our customer also uses the flake ice to produce so-called slurry ice.Technical data + installation details

- Flake ice plant, type FLIP80-R717-ac

- Automatic ice storage, type MIS40b

- Refrigerant: R717 (NH3 / ammonia)

- Economizer

- Ice conveyor system, 21 meters length

Ice production with fully automated ice conveying for process optimization in chemical plant

Ice production with fully automated ice conveying for process optimization in chemical plant

Technical data + installation details

- Flake ice plant, type FLIP100

- Water pre-cooling

- Refrigerant: NH3, ammonia

- Heat recovery (40°C hot water)

- Containerized ice storage, Type MIS-23

Ice production

- Conveyor container with

- 2x pneumatic conveying

- 2x compressed air cooler

- 2x inclined screw conveyor

- Integration into central control system

Renewal of ice production for quality improvement in pigment production

Renewal of ice production for quality improvement in pigment production

Technical data + installation details

- Flake ice plant, type: FLIP40

- 40 tons of flake ice production per day

- Water pre-cooling

- Refrigerant NH3, ammonia

- Glycol cooling for ice storage and conveying air

- Mobile ice storage, type MIS-23

- Silicone free design

2x ice conveyance, ice distribution

- Ice weighing over weigh belts

- Pneumatic ice conveying

- Conveying air cooling

- Switch container with 5-way ice switch

- Integration in central control system

Liquid chillers for Dubai's largest beverage bottler

Liquid chillers for Dubai's largest bottling company

Technical data + installation details

- 1050 kW cooling capacity

- Wet bulb temperature: +31°C

- Cooling: 12°C --> 5°C

Fresh water cooling

- 2800 kW cooling capacity

- Wet bulb temperature: +31°C

- Cooling: 45°C -> 25°C

Underground chiller for Brazilian gold mine

Underground chiller provides cooling for shaft sinking in Brazil

Technical data + installation details

- Underground ventilation system, type Underground Chiller UC 500

- Cooling capacity: 630 kWR

- Power supply: 460V/3Ph / 60Hz

- Delivery ex works: 4 weeks

- High energy efficiency: COP 5.7

Ice production for South African underground mining

South African gold mine benefits from energy savings Ice production on surface

Technical data + installation details

- 4 x plate ice machines, type PLIP 220

- 4 x plate ice machines, type PLIP 200

- all incl. ice breaking and ice removal system

- 2 x Containerized chillers, type CCWP800-20K

- Total cooling capacity: approx. 12500 kWR

- Power supply: 525V / 3Ph / 50Hz

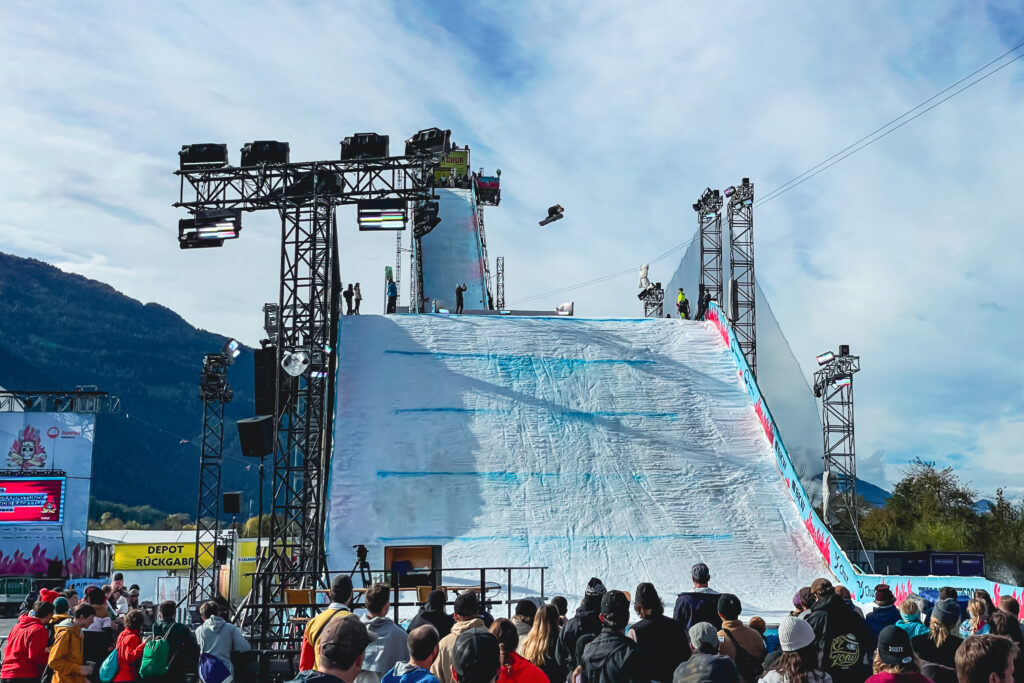

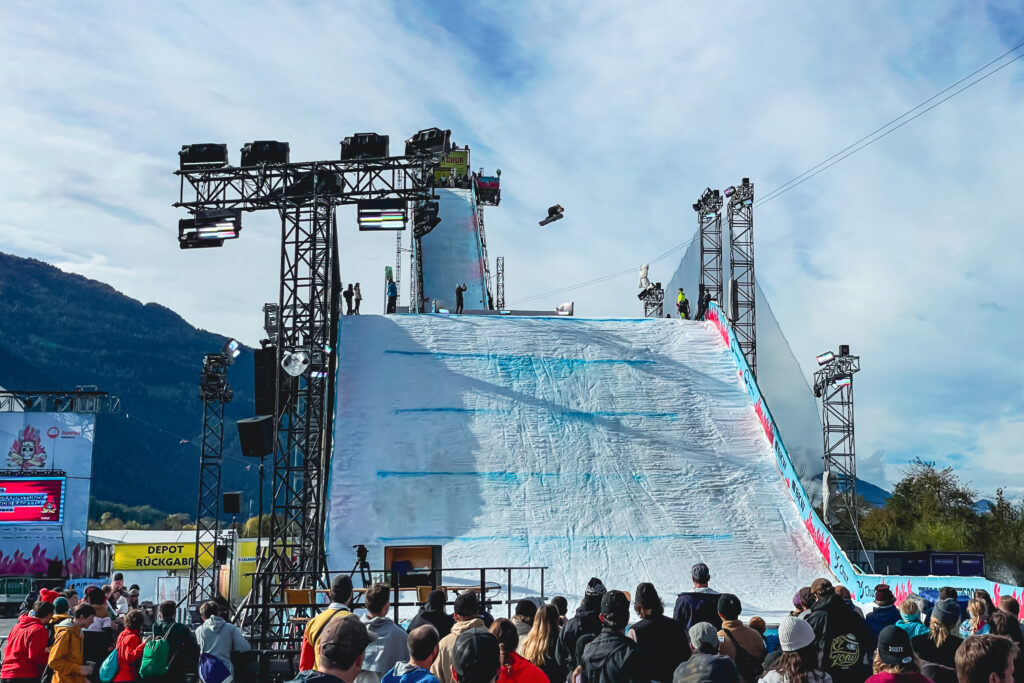

Snow for FIS Freestyle World Cup

Snow for FIS Freestyle World Cup

Technical data + installation details

- snowPRO70

- 34 tons of flake ice per day

- 20 feet container

- approx. 50 meters conveying distance

2014 Zurich, Switzerland

- 2x snowPRO100

- a total of approx. 90 tons of flake ice per day

- 2x 40 feet container

- approx. 50 meters conveying distance per unit

KTI snowPRO technology from Bangkok to Taiwan

KTI snowPRO technology from Bangkok to Taiwan

Snow fun in Sauerland, Germany

Snow fun in Sauerland, Germany

KTI snowPRO as a guarantor for the opening of the season

The details at a glance

Technical data + installation details

- 1x snowPRO260 (2020)

- 1x snowPRO260 (2022)

Flake ice

- 1x snowPRO230 (2014)

- 2x snowPRO210 (2018)

- 2x snowPRO200 (2019)

- 1x snowPRO210 (2020)

Snowmaking on top of glacier Titlis

Glacier snowmaking at 3000m altitude on the Titlis

KTI snowPRO100 transported in modules to 3000m altitude

The details at a glance

An ice filling station for La Reunion

Modern "ice filling station" for fishing in La Reunion

Ice production with automatic billing system

In 2019, we replaced an old existing plant in the port of La Reunion with a modern ice production facility. To reliably supply local fisheries with flake ice, our FLIP (Flake Ice Plant) produces 15 tons per day. The plant is operated - similar to a gas station - by the customer himself.

Already in the fall of 2018, we received the order from our customer to develop a new, modern ice production for the port on La Reunion. In addition to the ice production itself, which meets the latest technical standards, storage, transport and weighing were also required. The ice production plant was designed with ammonia (R717) as refrigerant. This ensures high energy efficiency. Likewise, in the event of a leak, no damage to the environment or climate is to be expected, which is important to both our customer and us. The produced ice is stored in an ice warehouse with a room temperature between -5°C / 23°F and -7°C / 19°F to keep the flake ice storable. Our customer has chosen a batch weighing system for ice, which is designed to weigh up to 450 kg / 990 lbs per weighing. The desired weight is set via a terminal PC, which is installed in a separate compartment from the technology. Access to it is realized via a chip-card system. The chip cards also serve to authenticate the ice cream customer for the integrated billing system. Once the ice has been weighed, it is transported directly to the docking ship via a pneumatic transport system. A flexible hose can simply be placed on the spot.The details at a glance

Technical data + installation details

- Shear ice machine, type FLIP15

- 15 tons of ice per day, 2 mm thick

- Ammonia as a natural refrigerant

- 23 tons ice storage, type MIS23

- Weighing system, WSC450

- Billing system, KISS

- Pneumatic conveying of flake ice on ship

- Integrated compartment for access for ice buyers and operation of the equipment

- Fully containerized

100 ton ice production for Europe's largest and most modern fish packer

Flake ice plant, automatic stainless steel ice storage system supplied to Europe's largest fish shipping center in Denmark

In February 2018, a Danish logistics company for fish approached us with the challenge of designing a plant that would meet their specific needs while at the same time fulfilling the highly demanding hygiene standards. This essentially involved a flake ice production of 100 tons of ice per day and an ice storage with a capacity of 90 tons. Furthermore, the ice has to be conveyed into the hall over a distance of 36 meters.

The flake ice plant was too large to be accommodated in the factory. Therefore, we installed the machines in standard shipping containers. This approach made it possible to place the ice machine, which can produce 100 tons per day, and the associated 90-ton ice storage system with our proven ice rake system next to the outer wall of the factory. At the same time, we planned to convey ice over a distance of almost 40 meters from the ice production unit to four ice batching units. Each ice feeder can only hold about 150 kg of ice at a time, and each meter of distance reduces the flexibility of supply. We realized this with an optimized control of the ice discharge system. Another challenge was the design of the machines themselves, as the ice must be hygienically spotless at all times. This meant leaving as few hard-to-clean corners and gaps as possible. The antibacterial properties of stainless steel and its high resistance to cleaning agents virtually rule out contamination of the ice while also making it easier to clean the components. As a refrigerant for ice production, we have used ammonia (NH3), which is ecologically unproblematic and is basically available in unlimited quantities. In combination with a so-called economizer and a water pre-cooler, we increased the energy efficiency by approx. 10% compared to similar plants. The plant has already been commissioned in Q3 2018 and fine tuning and interfaces to the fish processing plant have been established.The details at a glance

Technical data + installation details

- Flake ice plant, type FLIP 10

- Automatic ice storage, type MIS-90b Premium, in complete stainless steel

- Water pre-cooler

- Refrigerant: R7171 / NH3 (ammonia)

- 36 meters stainless steel ice conveyor in main building

- 5 outlets automatically controlled

Concrete cooling and heating for Argentine dam

Concrete cooling and heating for Argentine hydropower project enables year-round mass concrete production

Massive components and extreme temperatures

The details at a glance

Technical data + installation details

- 1x HWS1000 type hot water system

- 3x clean air silo heater type OLH1000

- Air nozzles for the silos

- Insulated air ducts with automatic damper control

Concrete cooling

- 1x plate ice machine type PLIP120, with integrated ice water cooler

- 1x MIS23 type automatic ice storage system

- 1x silo cooling with cold air of type CCAP800

- 1x air purifier / airwasher

- 1x CCWT58 type insulated cold water tank

We are here for you

How would you like to be contacted?

„*“ zeigt erforderliche Felder an

„*“ zeigt erforderliche Felder an

„*“ zeigt erforderliche Felder an